A Process Costing System Quizlet

A process costing system quizlet. In a job order cost system the unit cost is the total cost per job divided by the units produced. Click card to see definition. Current period cost plus the cost of beginning inventory c.

A process costing system was used for a department that began operations in January. A process costing system accumulates costs when a large number of identical units are being produced. Every company has its own unique costing methods that do.

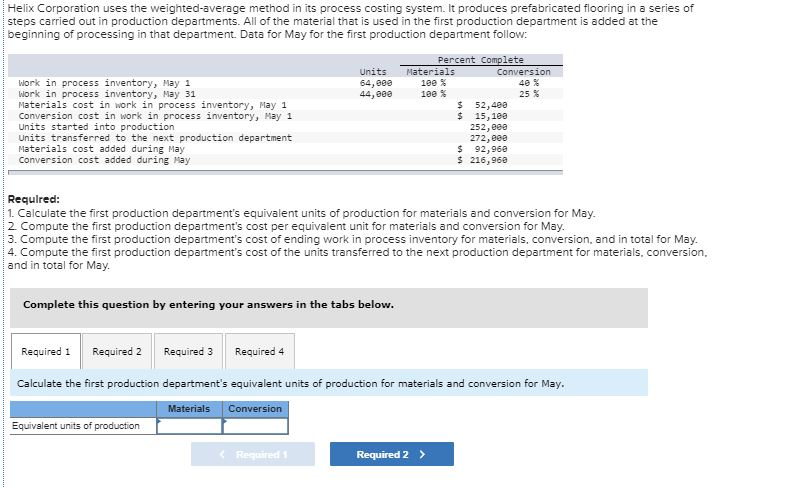

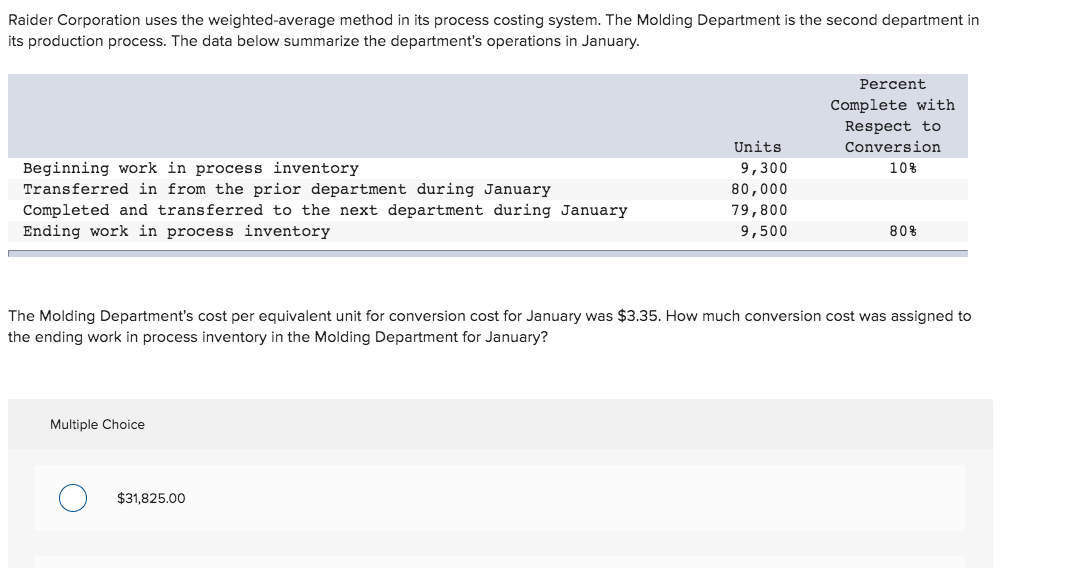

Monthly conversion costs are allocated between ending work in process and units completed. Is used to assign product costs in a mass manufacturing environment where a large number of similar items are produced. A process costing system is employed in those situations where.

Costing System the process of accumulating classifying and assigning direct materials direct labor and factory overhead costs to cost objects which most commonly are products services or projects. Process costing involves averaging costs for a particular period in order to obtain departmental and cumulative unit costs. What is a Process Costing System.

Tap card to see definition. A costing system used in situations where many different products jobs or services are produced each period. A job order cost system totals costs when the job is completed.

When thinking about the appropriate product costing system it will not necessarily fit into one of these three categories that is job order costing system a process costing system or an operation costing system. Activity based costing ABC is a costing system that was developed in the 1980s as a result of an increasing awareness in businesses of the deficiencies of traditional approaches to production overhead absorption. A process cost system totals costs at the end of a period of time.

Process costing is the only reasonable approach to determining product costs in many industries. Current period cost less the cost of beginning inventory d.

Learn process costing chapter 17 with free interactive flashcards.

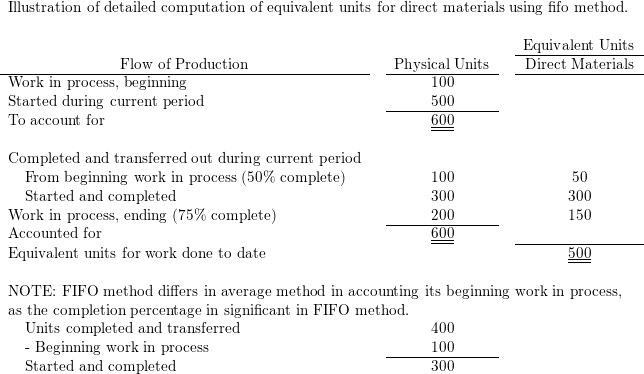

Multiple Choice 31 many different products jobs or batches of production are being produced each period. Process costing is the only reasonable approach to determining product costs in many industries. Is used to assign product costs in a mass manufacturing environment where a large number of similar items are produced. Process costing is the optimal system to use when the production process is continuous and when it is difficult to trace a particular input cost to an individual product. A process costing system was used for a department that began operations in January. The point at which costs are totaled. Click card to see definition. Only current period cost b. In this situation it is most efficient to accumulate costs at an aggregate level for a large batch of products and then allocate them to the individual units.

What is a Process Costing System. Process costing involves averaging costs for a particular period in order to obtain departmental and cumulative unit costs. I Describe the principal deficiencies in the traditional product costing system which ABC seeks to correct. Every company has its own unique costing methods that do. As its name suggests process costing system is the branch of cost accounting which is applied where production of a product takes more than one processes to complete for example the production of shoes from leather goes through cutting. In a process costing system overhead is allocated to departments after being applied to units of product. A job order cost system totals costs when the job is completed.

Post a Comment for "A Process Costing System Quizlet"